Systems

The design of our customized pelletizing systems is a five-step process:

Establish

Develop

Fabricate

Install

Train

How a Typical Pelletizing Plant Works

The Pin Mixer receives manure from the storage bin and feeder, mixes it with binder, pelletizes and sends the pellets to the Dryer.

The Dryer dries and cools the pellets, discharging them onto a conveyor belt that carries them to the Screen

The Screen removes and recycles oversized and undersized pellets, sending the “good” ones to the pellet storage bin, located outside the building.

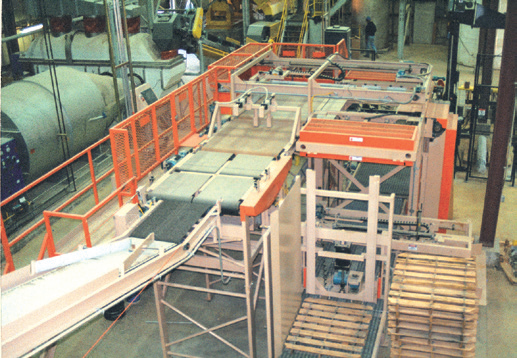

The Bagger takes the pellets from the pellet storage bin and automatically fills a FIBC or other package.

The Palletizer & Stretch Wrapper arrange the filled bags on pallets, stacking them for shipment and stretch-wrapping them to the pallet for stability in transport.

With a Mars Mineral Pelletizing System, you’re helping to reduce environmental and public health problems by using an agricultural waste product.

See our equipment in action

Limestone Pelletizing

Limestone PelletizingDuration: 14:45

A brief overview of our pelletization system.

Deep Drum Pelletizer

Deep Drum PelletizerDuration: 9:18

Our Deep Drum Pelletizer in action.

Disc Pelletizer

Disc PelletizerDuration: 0:39

Our Disc Pelletizer in action.