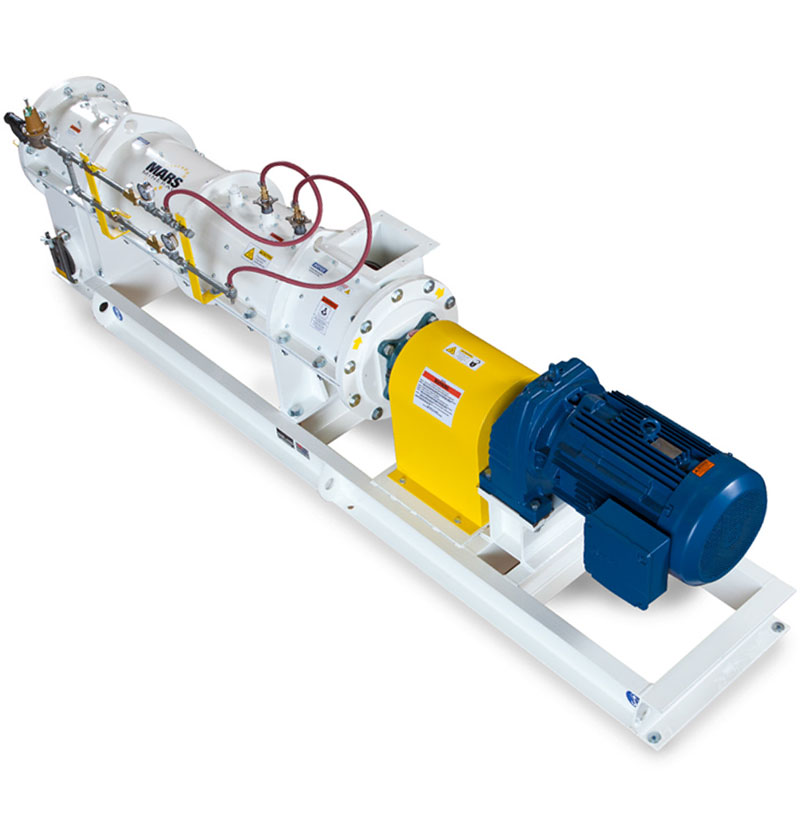

Pin Mixer

The Mars Mineral Pin Mixer is a pin-type solids processor designed for applications requiring high energy input to materials for mixing or micro-pelletizing. It is a high-speed, conditioning and micro-pelletizing device that converts dust into small agglomerates through the action of a high-speed rotor shaft and pin assembly, and the addition of liquids such as water, binders, oil or surfactants.

Application

The Pin Mixer is ideally suited for micro-pelletizing, agglomerating, or conditioning powdered materials, such as carbon black, tire char, cement kiln dust, manure, pigments, coal dust, pesticides, electric furnace baghouse dust, limestone fines, graphite, coke, petroleum coke fines, bauxite and silica fume for further processing in a pelletizer.

Pin Mixer |

Used as Pelletizer | Used as Mixer | End Product | Capacity | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Shape | |||||||||||

|

Yes | Yes | 0.01 - 0.20 in. dia. 0.30 - 4.75 mm |

Spherical to irregular | 10 - 2,200

ft3/hr 0.28 - 62.3 m3/hr |

|||||||

- Straight-forward dedusting/dust wetting

- Solids-liquid mixing

- Micro-pelletizing

- Preconditioning

- Chemical reaction

The Mars Mineral Pin Mixer features a cylindrical, stationary shell with a length-to-diameter ratio between 4:1 and 5:1. Inside the shell is a replaceable rubber liner and a shaft with radially-extending rows of pins in a helix pattern. There is a close tolerance between the tips of the pins and the inside of the mixer shell.

Shaft rotational speed, and therefore tip speed, is high (several hundred RPM), which is higher than the speed of traditional paddle mixers, pug mills and Ampel conditioners.

The material enters at one end of the cylinder and is whipped by the pins as it moves from the inlet, through the shell and to the bottom outlet. As a fine spray of liquid is added at the entry section and distributed throughout the powder, fine mixing and micro-agglomeration will occur. The end result is a wetted, agglomerated and densified micro-pellet.

Pin Mixer Specifications

| Model | Diameter | Length | Capacity (ft3/hr) | Capacity (m3/hr) | HP |

|---|---|---|---|---|---|

| 8D32L | 8" | 32" | 10 | 0.28 | 20 |

| 12D54L | 12" | 54" | 40 | 1.13 | 40 |

| 16D80L | 16" | 80" | 100 | 2.83 | 50 |

| 20D90L | 20" | 90" | 180 | 5.10 | 75 |

| 22D90L | 22" | 90" | 225 | 6.37 | 100 |

| 26D100L | 26" | 100" | 365 | 10.33 | 100 |

| 30D120L | 30" | 120" | 550 | 15.57 | 150 |

| 40D160L | 40" | 160" | 1,300 | 36.81 | 250 |

| 48D190L | 48" | 190" | 2,200 | 62.30 | 350 |

Note: Capacity throughput based upon free flowing material.

Specifications and dimensions are for general use only.

Actual HP may change depending on material bulk density.