Ampel Horizontal Pelletizer

The Mars Mineral Ampel Horizontal Pelletizer is a rapid- agitation device used to mix, condition and pelletize dust, fine powders and other materials. This equipment produces either a conditioned, wetted product or a granular, free-flowing agglomerate. It features a wide range of applications for conditioning and pelletizing at capacities ranging from one-half tph to 50 tph.

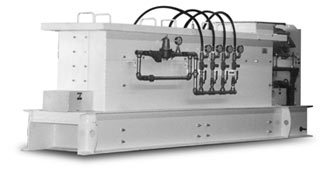

The patented design of the Ampel pelletizer features a rubber bottom trough with a single-shaft rotor assembly that extends the length of the trough. Elongated mixing arms with specially-designed wedge-shaped mixing blades extend radially from the assembly. Either a variable or constant-speed drive is used to power the assembly.

The blades are furnished in a variety of metal compositions. The sharp leading edges of the blades face the direction of rotor rotation, with the speed of rotor and blades adjusted to the correct movement, conditioning/pelletizing action, and through-put of the material being processed.

Ampel Pelletizer |

Used as Pelletizer | Used as Mixer | End Product | Capacity | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Shape | |||||||||||

|

Yes | Yes | 0.2 - 1.0

in. dia. 5 - 25 mm |

Irregular | 75 - 1,250 ft3/hr 2.1 - 35.4 m3/hr | |||||||

Detail shows Ampel trough design and wedge-shaped mixing blades of the rotor assembly.

Detail shows Ampel trough design and wedge-shaped mixing blades of the rotor assembly.

- Straight-forward dedusting/dust wetting

- Solids-liquid mixing

- Micro-pelletizing

- Preconditioning

- Chemical reaction

The bottom of the trough is formed of flexible rubber, which is attached to the stationary upper trough, producing a flexing surface that resists material buildup, improves material flow and increases wear resistance. For applications in which rubber cannot be used, other materials including metal or plastic bottoms may be used.

The Ampel is equipped with a water spray system above the inlet section of the pelletizer to apply finely atomized water spray or binder additives.

The Ampel unit provides granulation of agricultural chemicals, fertilizers, pesticides, chemical consumer products, carbon powders and flue dust from dust collectors. It conditions flyash, cement or lime kiln dust, foundry dust, iron oxide, friction material waste, lead fume and zinc oxide.

The Ampel is driven with a direct shaft mounted gearbox motor combination and is available with an optional VFD control panel.

The Ampel is also ideal for processing moist difficult-to-feed materials, combining moist and dry feed, mixing two or more materials and preparing feed materials for subsequent processing.

Ampel Horizontal Pelletizer/Conditioner Specifications

| Model | Trough Width | Trough Length | Capacity (ft3/hr) | Capacity (m3/hr) | HP | Length | Width | Height | Weight (lb) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A-150 | 1'-0" | 5'-0" | 75 | 2.1 | 5 | 7'-3" | 1'-5" | 2'-8" | 1,400 | |||

| A-175 | 1'-6" | 7'-6" | 175 | 5.0 | 10 | 10'-9" | 2'-2" | 3'-7" | 2,800 | |||

| A-210 | 2'-0" | 10'-0" | 375 | 10.6 | 15 | 14'-0" | 3'-0" | 4'-5" | 5,000 | |||

| A-315 | 3'-0" | 15'-0" | 750 | 21.2 | 30 | 18'-9" | 3'-10" | 5'-2" | 11,000 | |||

| A-418 | 4'-0" | 18'-0" | 1,250 | 35.4 | 50 | 22'-6" | 4'-10" | 6'-10" | 19,500 | |||

NOTE: Capacity based upon free flowing material.

Specifications and dimensions are for general use only.