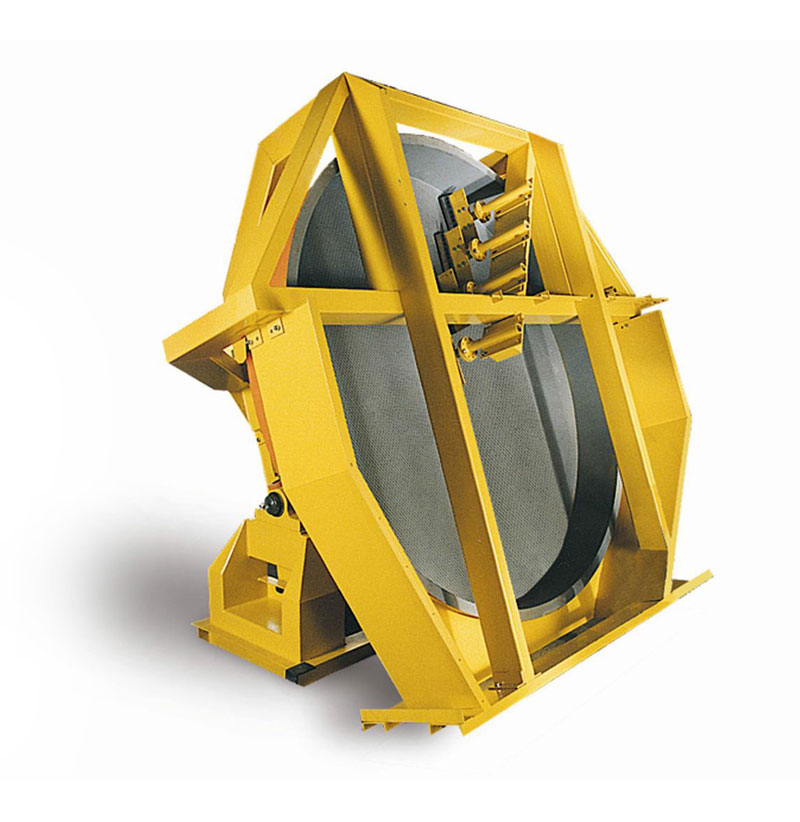

Disc Pelletizer

The Mars Mineral Disc Pelletizer is an adjustable pan device utilized in micro-pelletizing, pelletizing and conditioning applications in which a shallow pan and a smaller retained burden are desired. It can be used to pelletize materials such as taconites, copper, nickel, lead and zinc concentrates. Other applications include pelletizing of reclaimed sludge, moist filter cakes, coal, flue dusts, limestone, fertilizers and ores.

Disc Pelletizer |

Used as Pelletizer | Used as Mixer | End Product | Capacity | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Shape | |||||||||||||

|

Yes | No | 0.03 - 1.5 in. dia. 0.85 - 3.8 mm |

Spherical | 19 - 3,500 ft3/hr 0.54 - 99.1 m3/hr | |||||||||

The Mars Mineral Disc Pelletizer consists of a pan, rocker deck, plow support with plows, spray system and ust cover which are supported on a heavy structural frame and base.

The pan is driven by heavy-duty gear reducer that is mounted directly on the output shaft.

Mars Mineral's Disc Pelletizer is equipped with binder-spray system for use in micro-pelletizing, pelletizing or conditioning of a wide range of materials.

Mars Mineral's Disc Pelletizer is equipped with binder-spray system for use in micro-pelletizing, pelletizing or conditioning of a wide range of materials.

Changes in pan rotational speed can be made through an optional control panel with a VFD. The pan angle is adjustable within a range of 20 degrees to suit various pelletizing

The Mars Mineral Disc Pelletizer is equipped with a binder spray system which includes piping, tubing, nozzles, pressure gauges, valves, pressure regulator and strainer. For extremely dusty or toxic applications, Mars Mineral will also provide a discharge chute and a dust cover as optional items.

This unit is a front feeding device. Various feeders are used in conjunction with it to accommodate a range of materials and accuracies. Selection may be made from volumetric screw feeders, belt or table feeders and gravimetric weigh belt feeders.

Disc Pelletizer Specifications

| Model | Diameter | Depth | Capacity (ft3/hr) |

Capacity (m3/hr) |

HP | Length | Width | Height | Weight (lb) |

|---|---|---|---|---|---|---|---|---|---|

| P-30 | 3' | 8" | 19 | 0.54 | 1 | 4'-6" | 4'-0" | 4'-0" | 1,100 |

| P-45 | 4.5' | 9" | 62 | 1.75 | 3 | 4'-9" | 6'-1" | 6'-3" | 1,900 |

| P-60 | 6' | 10" | 112 | 3.17 | 5 | 6'-7" | 7'-5" | 7'-11" | 4,000 |

| P-80 | 8' | 1'-1" | 250 | 7.1 | 15 | 8'-8" | 9'-5" | 10'-0" | 12,000 |

| P-100 | 10' | 1'-31/2" | 375 | 10.6 | 25 | 11'-9" | 12'-4" | 12'-3" | 16,000 |

| P-120 | 12' | 1'-6" | 625 | 17.7 | 40 | 13'-2" | 15'-0" | 14'-8" | 28,000 |

| P-140 | 14' | 1'-8" | 925 | 26.2 | 60 | 15'-1" | 17'-0" | 16'-6" | 34,000 |

| P-160 | 16' | 1'-10" | 1,400 | 39.6 | 75 | 17'-2" | 19'-0" | 17'-7" | 38,000 |

| P-180 | 18' | 2'-0" | 1,875 | 53.1 | 100 | 19'-0" | 21'-0" | 20'-4" | 50,000 |

| P-200 | 20' | 2'-2" | 2,500 | 70.8 | 125 | 21'-8" | 24'-7" | 24'-3" | 70,000 |

| P-220 | 22' | 2'-4" | 3,125 | 88.4 | 150 | 22'-7" | 26'-7" | 26'-11" | 80,000 |

| P-250 | 25' | 2'-8" | 3,500 | 99.1 | 200 | 24'-10" | 29'-7" | 27'-6" | 95,000 |

CAPACITY IN CUBIC FEET PER HOUR THROUGHPUT, BASED UPON FREE FLOWING MATERIAL. SPECIFICATIONS AND DIMENSIONS ARE FOR GENERAL USE ONLY.

Download Page as a PDF