What Is Pelletization of Biochar and Why It’s Important for Sustainability

by Bill Booher

Biochar, a type of charcoal, is produced from biomass by heating organic material, such as wood, crop residues, or animal manure, in the absence of oxygen, in a thermochemical conversion process called pyrolysis. Pyrolysis converts the organic material into biochar, a stable pyrogenic carbon-rich material that can be used as a soil amendment, fertilizer, and energy source.

Biochar is known for improving soil fertility and structure, increasing water retention, reducing greenhouse gas emissions, and sequestering carbon in the soil (in a good way) for thousands of years. It is also used as a filtration medium, a livestock feed supplement, and in some industrial applications. Biochar production can be done on a small scale by individuals or communities or on a larger scale by commercial operations.

What Is Biochar Pyrolysis?

Pyrolysis of biomass is a thermochemical process of heating organic materials in the absence of oxygen. Pyrolysis occurs at high temperatures, typically between 500 and 1000oC. in a closed vessel or a kiln. At these temperatures, the organic material breaks down into biochar, syngas, and volatile oils and is collected through a condensation system. The quality and quantity of the products depend on several factors, including the type of biomass, the temperature and duration of the process, and the heating rate. The resulting biochar is a solid, carbon-rich material that can be used as a soil amendment, fertilizer, or energy source. Syngas is a gas that can be used to generate electricity or heat. The volatile oils can be used to produce bio-oil, which can be used as a carbon-negative fuel.

Pyrolysis and biochar production have the potential to be sustainable practices that can help to reduce greenhouse gas emissions and improve soil health.

|

Biochar Pelletization

Biochar can be crushed or ground into a fine powder, but it is often more practical to pelletize or agglomerate it using pelletizing technology.

Biochar pelletization can be a cost-effective way to produce a high-quality biochar product. It can also help to reduce the environmental impact of biochar production by reducing the amount of waste produced. Pelletizing biochar has several advantages, including making it easier to handle, transport, and store.

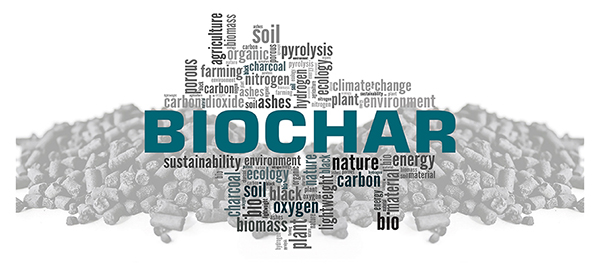

Mars Mineral Pin Mixer

Mars Mineral Pin Mixer

What Is Pelletizing?

Pelletizers are commonly found in the biomass and wood pellet industry, and animal feed, fertilizer, tire pyrolysis, mining, chemical, and consumer products industries.

Pelletizing technology or agitation agglomeration equipment includes pin mixers, disc pelletizers and deep-drum pelletizers. This process converts fine dusts and powders into spherical-shaped pellets without the need for pressure or heat but rather an agitation of the material in the presence of a binder, usually just water.

The benefits of pelletizing include eliminating fine dust particles and the improvement of material flowability and densifying. This results in reduced worker exposure to airborne dust, improved environmental conditions in the plant, the ability to recycle, reuse or produce a saleable product, or simply to provide a non-dusty product for disposal.

Agricultural Sustainability

The use of pelletizers for biochar production is a sustainable practice that contributes to material circularity and the circular economy. By converting organic waste into a valuable soil amendment, pelletizers can help reduce the amount of waste going to landfills and promote the use of renewable resources.

Biochar pellets can be a useful soil amendment for agriculture and home gardeners. Biochar pellets are made from fine-grained biochar that is compressed into small, easy-to-use pellets. They can be made from various feedstocks, such as wood chips, agricultural waste, and even sewage sludge.

For agriculture, biochar pellets can be spread over fields using conventional seed drills, broadcast spreaders, or other types of fertilizer application equipment. Home gardeners can add biochar pellets directly to soil in garden beds or containers. Biochar pellets can help to increase the availability of nutrients and improve the overall health of plants. They can also help to reduce soil erosion and leaching of nutrients.

Biochar pellets should be used in combination with other fertilizers and soil amendments and should not be relied on as a sole source of nutrients. However, biochar helps to slow the release of nutrients from the fertilizer, which can help to improve plant growth. Biochar-based fertilizers are also more sustainable than traditional fertilizers, as they do not contain synthetic chemicals.

Biochar and Nutrient Management

Biochar-based slow-release fertilizers (SRFs) have gained increasing attention due to the biochar’s unique properties, such as its high porosity, stability, adsorption capacity, and microbial activity.

SRFs are fertilizers that release nitrogen slowly over time. This contrasts with conventional fertilizers, which release nitrogen quickly. SRFs are often used in organic farming, as they help reduce the amount of nitrogen lost to leaching.

When added to soil, biochar helps to improve the soil’s ability to retain nitrogen because biochar is attracted to N. Biochar also helps to improve the soil’s microbial activity, which can help to break down nitrogen-containing compounds and make them available to plants.

SRFs that contain biochar can also help to improve crop yields. Plants have a better chance of absorbing the nitrogen that is available to them, and they can grow more efficiently. Overall, SRFs that contain biochar are a sustainable and effective way to fertilize crops.

Integrated production methods, such as granulation, make SRFs more effective. Granulation involves the production of pellets containing both biochar and nutrients. This method can improve the handling and storage of biochar-based SRFs and provide a more uniform nutrient release.

|

The effectiveness of biochar pellets will depend on the specific soil and cropping system, and careful management practices will be necessary to maximize their benefits.

|

The Benefits of Biochar

Improving soil fertility: Biochar can help to improve soil fertility by adding organic matter and nutrients to the soil. It can also help to improve soil structure and drainage.

Reducing greenhouse gas emissions: Biochar can help to reduce greenhouse gas emissions by sequestering carbon from the atmosphere.

Providing a renewable source of energy: Biochar can be used as a fuel to generate electricity or heat.

The Benefits of Biochar Pelletization

Ease of storage and transportation: Pelletized biochar is easier to store and transport than loose biochar.

Wider range of applications: Pelletized biochar can be used in a wider range of applications, such as in soil amendments, fertilizers, and energy sources.

Cost-effectiveness: Biochar pelletization can be a cost-effective way to produce a high-quality biochar product.

Environmental impact: Biochar pelletization can help to reduce the environmental impact of biochar production by reducing the amount of waste produced.

Takeaway Points

● Using pelletizers for biochar production contributes to material circularity and the circular economy by turning waste materials into a valuable resource for soil improvement, reducing the need for virgin materials and promoting sustainable practices.

● Pelletizing technology allows for a more efficient and consistent production of biochar pellets, reducing waste and increasing the yield of the raw materials used.

● Biochar pellets have a longer shelf life and are easier to handle and apply than loose biochar, making it more accessible to farmers and gardeners.

● The slow-release properties of biochar pellets help to improve soil fertility and reduce the need for chemical fertilizers, promoting sustainable agriculture and reducing the environmental impact of conventional farming practices.

● Biochar pellets can also be used for carbon sequestration, helping mitigate climate change’s effects by capturing and storing carbon in the soil.

In Conclusion

The future of biochar is promising. Biochar can potentially play a significant role in addressing several environmental challenges, including climate change, soil degradation, and deforestation. Biochar pelletization can also help to make biochar more accessible and affordable, which can help to increase its use and impact.

Mars Mineral offers pelletizing solutions for various applications, including biochar production, which contribute to the development and adoption of sustainable technologies. It is also important to use high-quality biochar pellets that have been properly produced and tested to ensure their effectiveness, safety, and marketability.